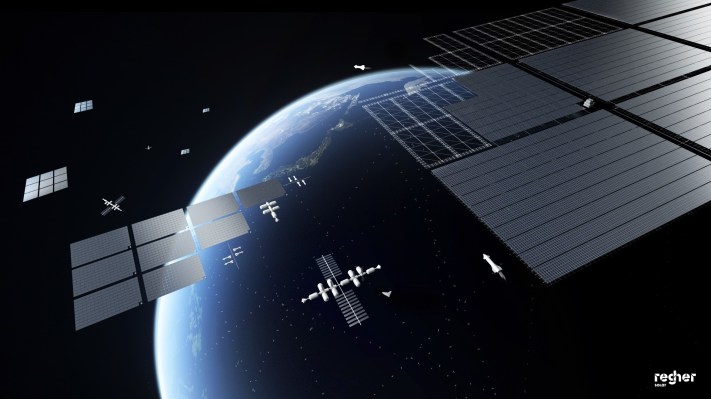

The math is fairly primary. How many satellites are going to go up over the subsequent decade? How many photo voltaic panels will they want? And what number of are being manufactured that match the invoice? Turns out the solutions are: loads, a hell of loads, and never almost sufficient. That’s where Regher Solar aims to make its mark, by bringing the price of space-quality photo voltaic panels down by 90% whereas making an order of magnitude extra of them.

It’s not precisely a modest objective, however fortuitously the science and market appear to be in favor, giving the corporate one thing of a tailwind. The query is of discovering the fitting stability between value and efficiency whereas remaining comparatively simple to fabricate. Of course if there was a simple reply there, somebody would already be doing that.

Solar cells to be used on the planet’s floor are very totally different from those being utilized in house. Because down right here there are few dimension and mass limitations, you can also make the cells larger, heavier, and fewer environment friendly — and less expensive. Space photo voltaic cells, alternatively, have to be extremely environment friendly, extraordinarily mild, and proof against the varied risks of house, akin to radiation and temperature fluctuation: a top-tier product that prices 5-10 instances as a lot and makes use of small-scale processes and costly supplies.

Regher Solar has created a space-grade photo voltaic cell that, whereas it doesn’t attain these devoted house photo voltaic ranges, isn’t that far off — but prices a fraction as a lot and could be made at scale with current processes. If you’re making a single $200 million geostationary satellite tv for pc, you don’t thoughts paying for the perfect panels on the market, because it’s solely a small a part of the general value. But if you happen to’re trying to deploy 10,000 small satellites with quick lifespans, panels begin making up much more of your invoice of supplies, and a 20 % efficiency hit doesn’t sound so unhealthy.

Stanislau Herasimenka, CEO and co-founder of Regher, defined that there’s no magic bullet to their product, however reasonably plenty of incremental enhancements and an understanding of what’s truly essential to the brand new house financial system.

“The tech has evolved in a high cost, low volume space,” he defined. “Space panels, they start from a very expensive substrate, usually germanium or gallium arsenic, and lots of expensive processing. Then there’s space grade interconnect, an expensive glass and carbon fiber or aluminum substrate, manual assembly… top performance and low degradation, but it’s totally not scalable. If they wanted 10 times more of these, they just couldn’t do it.”

Yet we’re clearly on our technique to doubling, tripling, and finally 10X-ing the variety of satellites being launched. They can’t simply slap terrestrial cells on there — they’d shortly fail — and the tried-and-true makers of fancy III-V cells received’t have almost sufficient inventory. So Regher took the perfect of each worlds to make their cells space-ready, however low-cost and capable of be made in a rush.

A Regher versatile silicon photo voltaic cell made with a 20-micron silicon substrate. Image Credits: Regher Solar

“Right now we’re running an R&D pilot line where we can make small quantities of panels — 50 kilowatts, about 5 percent of what the space industry does,” he mentioned. “But because we designed with silicon, and the package to be compatible with automated production, we should be able to transition from pilot to 10 megawatts, which is 10 times more than what the space industry does, in a year.”

Although the product is new, it doesn’t use any unique or unprecedented strategies, so ramping up like that actually could also be attainable. Herasimenka described a couple of of the modifications they made to attain space-like efficiency at terrestrial-like costs.

In the primary place they took the thickness of the silicon substrate approach down, that means it’s paradoxically far more proof against radiation, since it would take in much less. They additionally modified the impurities and doping in it in order that it cures at a low temperature, permitting what injury is triggered to be fastened by merely being heated to 80 levels Celsius. The coating, interconnect, and bonding are space-stable. There’s additionally much less house devoted to what you would possibly name the bezel, letting the sun-sensitive cells make up extra of the floor space. The plan can be to make them versatile (as demonstrated within the pictures right here), to higher match uncommon shapes and to extend bodily hardiness.

A lab technician exhibits the pliability of a Regher “solar blanket.” Image Credits: Regher Solar

Knowing how far to go trusted the shifting goal that’s the value and deliberate lifetime of a given constellation-bound satellite tv for pc. It’s counterintuitive, however it may be a hazard to a constellation firm like Starlink if their satellites carry out too nicely. With 1000’s of satellites, unit economics come into play — and also you don’t need them to be any higher or dearer than they need to be if the acknowledged plan is to interchange them 5 years from launch. If they’re nonetheless going at 100% then, you most likely may have saved some huge cash someplace alongside the road.

“Constellation designers design for a particular period of time in a particular orbit,” Herasimenka mentioned. “Nobody wants to live for 2 weeks, and nobody wants 15 years; mostly they go to low Earth orbit and only live there for 5-7 years. So we designed for this exact requirement. If they degrade after that, we don’t care because our customer doesn’t care.”

Regher taking its shot at this rising market earned it a spot in TechStars’ 2019 batch, after which they began speaking to producers and roughing out offers. They additionally snagged a NASA SBIR Phase I award and an NSF Phase II, totaling $1.1M. With prototypes and a few validating funding in hand, they collected $33M in LOIs over the summer time and have $50M extra being hammered out, Herasimenka mentioned.

As promising as that’s, the corporate wants to maneuver quick or threat others shifting in and consuming their lunch. “Everything can change in just a few years, and by the time an industry realizes it, the market opportunity is gone,” he mentioned. Clearly Regher Solar intends to be the one to grab up that chance, however they’re now on the lookout for vital funding to convey first their pilot, then later the complete scale manufacturing traces on top of things. They’re not able to announce the specifics, however Herasimenka mentioned they’ve a $5 million institutional fairness seed spherical that ought to shut earlier than the top of the yr, plus $750,000 from people.

With curiosity from established aerospace corporations and stamps of approval (through SBIR) of each NASA and the NSF, Regher appears nicely positioned to make its play. Whether the laborious half is designing the brand new panel or truly making it, although? They’re about to search out out.

#Regher #Solar #prepared #meet #house #industrys #demand #cheaper #photo voltaic #panels #TechCrunch

https://techcrunch.com/2021/10/14/regher-solar-is-ready-to-meet-the-new-space-industrys-demand-for-cheaper-better-solar-panels/