If there may be ever going to be a nationwide hydrogen financial system, we’re going to wish to vary a number of issues. One of them is how we produce hydrogen itself, the overwhelming majority of which comes from fossil fuels. SunGreenH2 brings a nanotech-level advance to inexperienced hydrogen manufacturing, supercharging electrolysis so orders of magnitude extra hydrogen will be cleanly made immediately from water.

Hydrogen is in use all over, however the lack of a scalable, inexperienced possibility for producing it has slowed its adoption. What’s the purpose of getting a hydrogen battery system for renewables if you need to supply that hydrogen from pure fuel, oil and coal?

The reply is the method of electrolysis, which separates water molecules into their constituent atoms, producing hydrogen and oxygen. Sounds nice, nevertheless it takes numerous vitality and costly components like platinum to supply the catalysts and membranes that make up the tech sandwich of any trendy electrolyzer cell. So inexperienced hydrogen is a number of occasions costlier than soiled hydrogen and tougher to make besides.

In comes SunGreenH2, which has made a serious enchancment to an important a part of these cells: the electrode. The firm claims that it may double hydrogen manufacturing, decrease the associated fee and scale back reliance on platinum and different uncommon components multi functional swoop.

“We are nanostructuring a proprietary alloy-based electrode that dramatically increases the surface area available for the reaction,” stated CEO and co-founder Tulika Raj. “For a given size of active area, [it] results in enhancement of current density (directly related to hydrogen production) by more than double. But that’s not enough, you need to to be scalable and manufacturable. So it doesn’t use precious metals — in this case we are reducing the amount needed by 30x.”

She stated that virtually all trendy electrolyzers can use this improved electrode. “The idea is to lift the entire industry,” she stated.

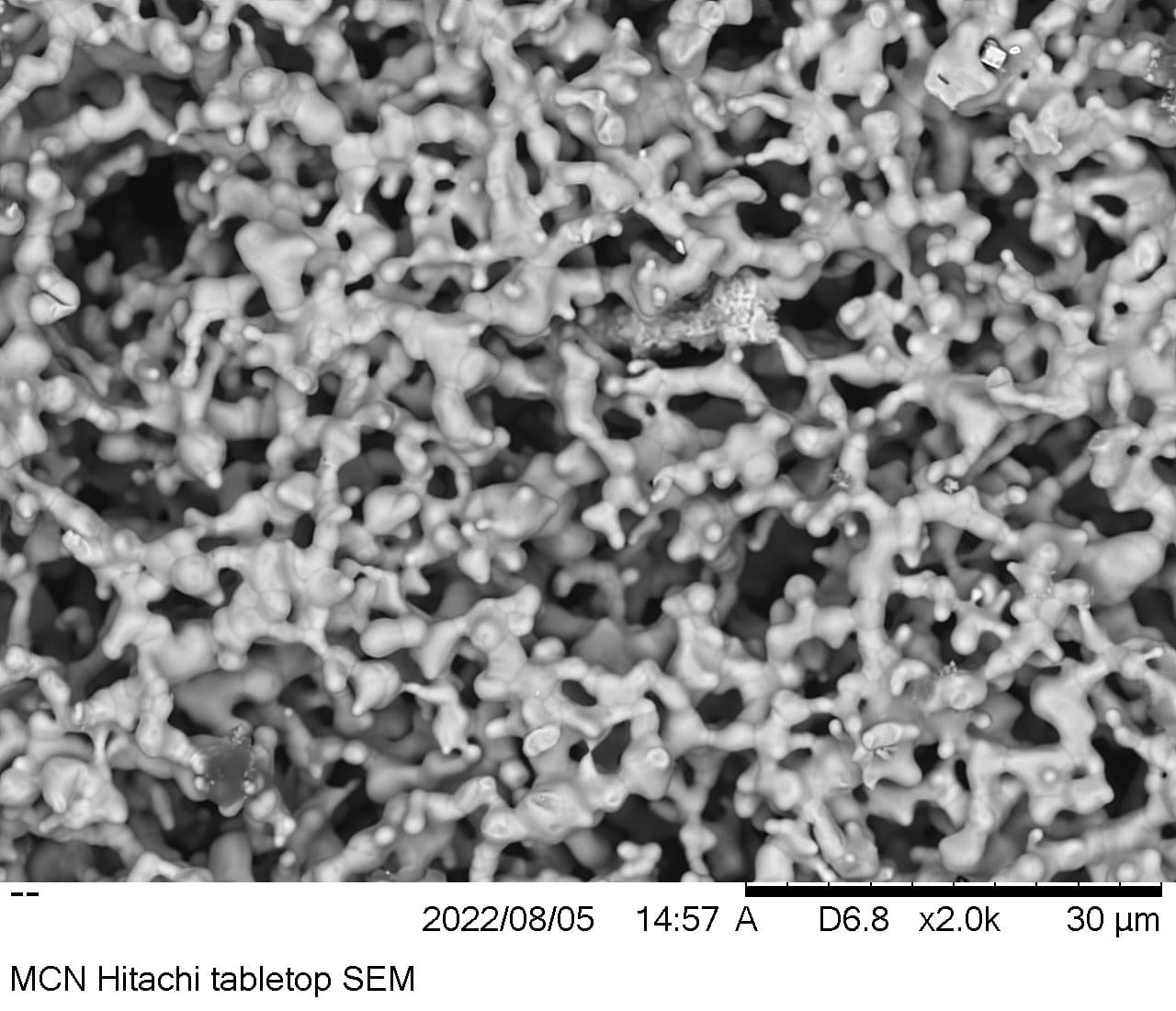

The nanostructure floor is the first advance, and you’ll see a scanning electron microscope picture of it right here:

Image Credits: SunGreenH2

It appears to be like a bit chaotic, however the materials is fastidiously engineered to work together with the opposite chemical parts of the electrolysis course of (primarily water and a catalyst), and by forming a kind of 3D sponge construction slightly than a flat or tough one, it doubles the floor space that response can occur on.

One weak point of nanostructures is that they’re very fragile and liable to degradation, decreasing their effectiveness (nonetheless miraculous) over time. SunGreenH2 has gotten out forward of this flaw with “the novel concept of sacrificing catalyst.”

“Increasing the surface area and tuning the crystallinity of the deposited materials results in improvement of the performance and stability, respectively, while using the sacrificing catalyst results in significant enhancement of the lifespan of the main catalyst,” Raj defined. “In current/existing technology, due to corrosion of the catalyst, the performance of the electrode reduces. In the technology developed by SunGreenH2, corrosion of the sacrificing catalyst results in enhancement of the surface area, which compensates for the impact of corrosion.”

SunGreenH2 co-founders Tulika Raj (left) and Saeid Masudy Panah. At proper, a prototype electrolysis stack with the corporate’s tech within the center someplace. Image Credits: SunGreenH2

In different phrases, this second materials pervades the construction, and its corrosion course of (in some way past my understanding) retains the primary catalytic floor contemporary.

The firm has raised a $2 million seed spherical led by SGInnovate, with participation from Vinci BV, Cap Vista, Entrepreneur First, SOSV’s HAX, she1K and Apsara Investments. Raj stated that this cash will go to establishing their first manufacturing services in Melbourne to fulfill the calls for of their early companions, that are confidential however embrace main vitality considerations within the EU, U.S. Canada, Japan and Singapore.

Though the intention at first is to promote the electrode part individually, subsequent yr it plans to associate with system integrators to supply complete electrolysis stacks and ultimately with bigger corporations to supply extra end-to-end options. “We can also apply our platform technology to fabricate similar green transition materials, i.e., electrodes, PTLs and bipolar plates for fuel cells, electrodes for batteries and photoelectrodes for direct solar to hydrogen panels,” Raj stated.

All that relies on their success in these early days, but when a inexperienced hydrogen revolution goes to occur, the trade should begin embracing applied sciences like this one sooner slightly than later.

#SunGreenH2s #nanoscale #engineering #double #inexperienced #hydrogen #manufacturing #TechCrunch

SunGreenH2’s nano-scale engineering could double green hydrogen production