Working since 2017 with Tokyo’s Waseda University, Nissan says it has developed and a brand new recycling course of that represents a extra environment friendly and cost-effective method of recovering rare-earth metals from electrical motors.

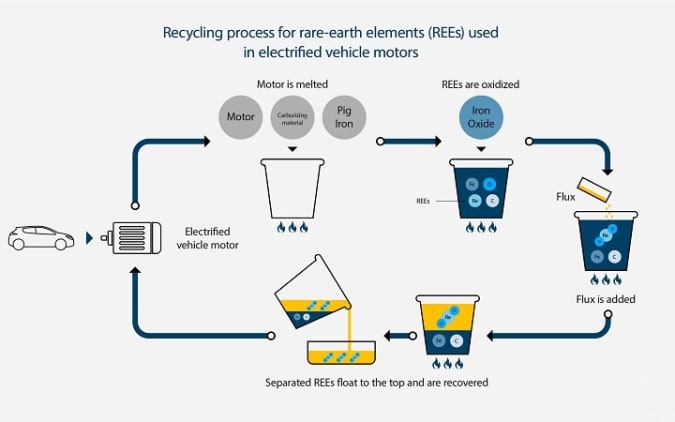

The course of itself includes heating a used motor to 1,400 levels Celsius (roughly 2,552 levels Fahrenheit) in order that it melts down. The firm then provides an iron oxide to the combination to oxidize the rare-earth metals, adopted by a borate-based flux. The latter substance causes the molten combination to separate into two liquid layers, with the rare-earth metals floating to the highest of the combination the place they are often simply eliminated.

In testing, Nissan claims it’s been capable of get better 98 % of a motor’s rare-earth parts utilizing the brand new recycling course of. The whole process additionally takes about half as a lot time as manually disassembling a motor, which is what Nissan at present does to recycle rare-earth metals. The firm hopes to implement the method by the mid-2020s.

Nissan

If we’re to have any likelihood to , discovering new and novel methods to recycle and reuse rare-earth metals will probably be very important. The 17 minerals that make up the rare-earth group are crucial to creating electrical automobiles, photo voltaic panels and wind generators. A 2018 research by the Dutch Ministry of Infrastructure discovered a scarcity of rare-earth metals is prone to restrict the world’s capability to satisfy the emission discount targets set out by the .

All merchandise really useful by Engadget are chosen by our editorial workforce, impartial of our dad or mum firm. Some of our tales embody affiliate hyperlinks. If you purchase one thing by means of one in all these hyperlinks, we could earn an affiliate fee.

#Nissan #testing #environment friendly #recycle #rareearth #metals #motors #Engadget