In order to have the ability to carry heavier payloads via deep house, NASA designed a light-weight rocket engine nozzle made from aluminum that may nonetheless stand up to the warmth of launches.

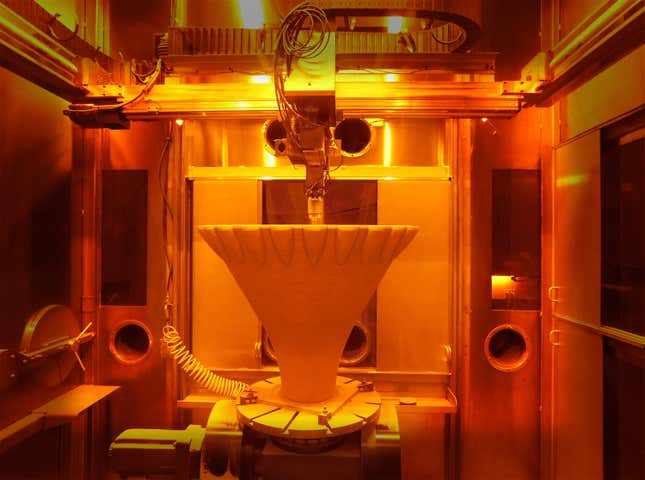

NASA lately examined two 3D printed nozzles on the Marshall Space Flight Center in Huntsville, Alabama, proving that they’ll function in essentially the most demanding deep house environments, the house company announced. Under a partnership with Elementum 3D, the NASA-funded Reactive Additive Manufacturing for the Fourth Industrial Revolution, or RAMFIRE, undertaking focuses on advancing light-weight, additively manufactured aluminum rocket nozzles.

The nozzles operated for practically 10 minutes throughout a number of scorching hearth assessments utilizing liquid oxygen and liquid hydrogen, in addition to liquid oxygen and liquid methane gasoline configurations with strain chambers in extra of 825 kilos per sq. inch. “This test series marks a significant milestone for the nozzle,” Paul Gradl, RAMFIRE principal investigator at NASA’s Marshall, mentioned in a press release. “After putting the nozzle through the paces of a demanding hot-fire test series, we’ve demonstrated the nozzle can survive the thermal, structural, and pressure loads for a lunar lander scale engine.”

Rocket engine nozzles are made from quite a lot of materials, together with graphite, ceramics or refractory metals. Aluminum has a significant benefit over different metals as it’s decrease in density and is due to this fact excessive energy whereas being light-weight. The solely drawback is that aluminum has a really low tolerance to excessive warmth, and that’s why it’s usually not used for additive manufacturing of rocket engine components.

RAMFIRE got down to create a weldable sort of aluminum that’s warmth resistant sufficient to be used on rocket engines. The RAMFIRE nozzles are designed with small inside channels that preserve them cool sufficient to forestall melting.

The means to fabricate light-weight rocket elements able to withstanding excessive structural masses would enable NASA to ship extra cargo to deep house locations. “Mass is critical for NASA’s future deep space missions,” John Vickers, principal technologist for NASA’s Space Technology Mission Directorate, mentioned in a press release. “Projects like this mature additive manufacturing along with advanced materials, and will help evolve new propulsion systems, in-space manufacturing, and infrastructure needed for NASA’s ambitious missions to the Moon, Mars, and beyond.”

The RAMFIRE nozzle can be constructed as a single piece utilizing superior 3D printing strategies, requiring far fewer bonds and considerably decreasing manufacturing time, based on NASA. Regular manufacturing, alternatively, could require as many as a thousand individually joined components. “We’ve reduced the steps involved in the manufacturing process, allowing us to make large-scale engine components as a single build in a matter of days,” Gradl mentioned.

The RAMFIRE aluminum materials and additive manufacturing course of was additionally used to assemble different rocket elements resembling a 36-inch diameter aerospike nozzle with complicated integral coolant channels and a vacuum-jacketed tank for cryogenic fluid functions.

For extra spaceflight in your life, comply with us on X (previously Twitter) and bookmark Gizmodo’s devoted Spaceflight web page.

#Nasa #assessments #3Dprinted #rocket #nozzle #deep #house #missions

https://gizmodo.com/nasa-test-3d-printed-rocket-nozzle-deep-space-missions-1850953328